How to make potato vodka with EasyDens

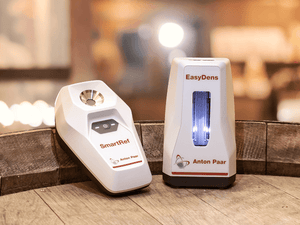

Produce your own potato vodka and control the fermentation and alcohol content with the Anton Paar EasyDens Digital Density Meter.

Viva la vita – viva la vodka

For many years, vodka was considered a medical drink. It has been used to treat colds, to disinfect wounds, and even to relieve toothache in small children. Vodka was considered a miracle drug that could cure a variety of diseases, including the plague.

Nowadays, vodka is often used as the base alcohol for various mixed drinks due to its neutral taste and high alcohol content. Typically, vodka has an alcohol content of 40 %v/v, but some of the Polish vodkas even have 96 %v/v, which is said to be the strongest liquor available for sale.

From potatoes to vodka

When you think of making vodka, the potato comes to mind. However, the potato was not brought to Europe until the 16th century. Before that, vodka was more typically made from everything that ferments, like corn, rice, or wheat. Vodka can be distilled from any agricultural product containing sugar or starch. Some distilleries make vodka from grapes, hemp seed, and coffee pulp. But potatoes have become popular as a substitute mash for vodka, giving the vodka an earthy tone.

Producing your potato vodka step-by-step

Carefully clean your potatoes as any remaining dirt will affect the purity and clarity of the resulting vodka. Boil the potatoes for approx. 15 - 20 minutes. After boiling, mash the potatoes and transfer the mashed potatoes to another pot. Fill with clean water and heat up to 60°C (140°F). Stir while the temperature rises. The enzymes will break down the carbohydrates in the potatoes to mash sugar. Keep the temperature for around 20 minutes and keep stirring. Then increase the temperature to around 67°C (153°F) and run for an hour.

Take a sample of the liquid and measure the specific gravity (SG) with EasyDens and the Brew Meister app. If the gravity is below 1.065 add sugar until the readings match this level.

Cool the potato mash down and let it sit overnight, this gives the enzymes more time to break down the starch in the potatoes to sugar.

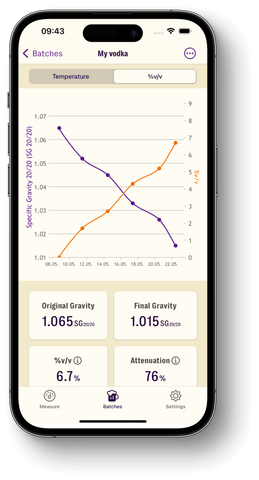

Take once again a sample of the liquid and measure the specific gravity. Store this value as original gravity in your batch. This is your gravity value before the fermentation takes place.

Fermentation

Only the mash-water is used in this step, so a lot of solids are discarded.

Yeast creation

To make a yeast starter, fill a previously disinfected mason jar with about 30 mL of water at a maximum temperature of 43°C (109°F). Add about 2 tablespoons of sugar and yeast to this water. The type of yeast determines the course of fermentation. Mix this mixture well and leave it for about 20 minutes to allow the yeast to rise.

Once the yeast starter is ready, mix it with the mash solution in a fermenter. Seal the fermenter at room temperature for at least 2 weeks. During this time, the mashed sugar is converted into alcohol and carbon dioxide. Check the fermentation approx. every 12 hours to remix any solids that float to the top.

Keep an eye on your fermentation at all times

During this time, the fermentation process of your potato mash can be controlled with the EasyDens Digital Density Meter. Take samples regularly and measure the °Brix content and the specific gravity. The values can be saved in batches and displayed graphically via the mobile app. This is a great way to control the sugar consumption and its conversion into alcohol. With the help of the measured specific gravity and the knowledge of the original gravity, EasyDens automatically calculates the approximate alcohol content.

Potato vodka distillation

Now the production of the “real” vodka starts!

Distillation means heating the previously fermented liquid in a still until it vaporizes. As alcohol boils at a lower temperature than water, distillation can separate the alcohol from the water. The vapor condenses into a pure liquid with a high alcohol content – your real potato vodka.

Collecting the distillates

The distilled product is not simply bottled during distillation as not all parts of the distillate are drinkable.

The first portion of the distillate has elevated levels of methanol and acetone, which can be harmful to those who drink it. This part is called the foreshot. You can easily identify this part of the distillate by its characteristic smell of nail polish remover.

The next part is called the head and is a mixture of methanol, acetone, ethyl acetate, and ethanol. It is not as undrinkable and dangerous as the foreshot, but it is still not used for the final product. It smells sweet and buttery, with a still pungent, solvent-like aftertaste.

The following part is the heart, which is your desired vodka and is typically collected at temperatures between 90 and 95°C (194 and 203°F).

The last part is called the tail, which is rich in fusel oil that produces undesirable off-flavors in the product and has the unpleasant smell of a wet dog.

Get a detailed insight into your vodka – use it or dilute it!

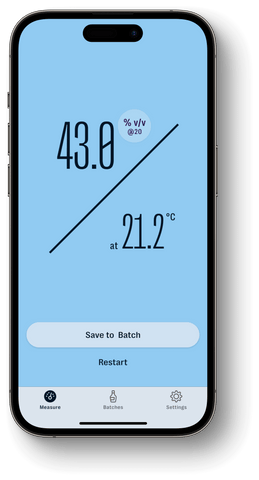

After the distillation, measure the alcohol content of your product with EasyDens and Proof Meister mobile app. Since the alcohol content after distillation is usually too strong to drink, dilute your product with water to the appropriate ABV. Typically, standard vodkas have an alcohol content of 40 %v/v (80°Proof).

Now your potato vodka is perfect to drink. Cheers!