Homebrewing Guide

Immerse yourself into the art and science of beer brewing!

Brewing beer has a very precise and calculated aspect to it and at the same time it is wildly artistic - giving you space for your own creativity in finding your unique beer brewing style and character.

With this step-by-step homebrewing guide you will learn what it takes to create and enjoy your own handcrafted beer.

Brew Day Preparation

Plan one day for the actual beer brewing process and three to five weeks for fermentation and maturation of the beer.

If you want your homebrew to result in the finest beer possible with its special aroma, you should use high quality raw materials.

You will need:

- A mix of ground malted grains

- Drinking water

- Yeast

- Hops

Prepare the setting and equipment as a first step on your brew day as it avoids stress with moving things during the brewing process.

This is the basic equipment you should have:

- Recipe

- Brewing protocol

- Brew kettle

- Food-safe barrels

- Measuring device to determine the wort extract/alcohol content

- pH tester

- Glass jars

- Big wooden spoon

- Funnels in different sizes

- Glass bottles

- Cooling coil (optional)

It is key to have a good recipe with the matching grain mix and hops type for it.

If you need inspiration, you might want to take a look at the collection of recipes on beerandbrewing.com.

Also consider the kind of water you are using. If the tap water is chlorinated or very hard, it can negatively affect the taste of the beer. One solution might be to use bottled water. The water must be fresh, low in lime and biologically safe. Water hardness is also an essential factor for the taste of the finished beer. Soft water is often used for light beers and harder water is preferred for dark beers.

Everything set - time to start brewing!

Beer Brewing Process

Mashing

![]()

Mashing is a steeping process with hot water during which the malt is hydrated, its enzymes are activated and the grain starches are converted into fermentable sugars.

The liquid/substance produced during this process is called wort.

The mashing phases in which the wort is heated at different temperatures are called rests.

To start the mashing process, pour the required amount of water into the brew kettle and heat to the starting temperature. If your brew kettle has temperature regulation and can be programmed, you can set all the temperatures and running times for the rests.

- Place the sieve in the brew kettle as required (that might depend on the kettle brand you are using) and pour the malted grain into the sieve.

- Stir well, then start the temperature run. If your brew kettle is not programmable: Heat and leave at required temperatures by manually operating the brew kettle.

- Ten minutes after mashing in you should do a pH test. The value should be approximately 5.6; if it isn’t you can take countermeasures like adding some lactic acid (80 %).

- Stir the mash in-between rests so grain and water mix well.

- Before the last rest you should do an iodine test. This will make the leftover starch visible. If the color stays light, it is fine; if the fluid has dark spots, it is not. In this case you should prolong the penultimate rest at 73 °C (163.4 °F).

When all the rests are finished, you can perform a first measurement of your wort (optional). It will show you the extract of your wort at this point in the brewing process – a first orientation for how much your original extract will be later on.

You can also use this first measurement to find out if something went wrong during your mashing process - e.g. too much starch is left over and was not transformed into sugar.

Lautering and Sparging

![]()

Lautering is the process of separating liquids from solids. Sparging is the rinsing of the mashed grains with brewing water in order to extract residual sugars.

You can either let the wort drain from the sieve into the brew kettle or rinse your mash, so all the wort is flushed out of the draff that you dispose of later.

Slowly take out the sieve and keep it a few inches above the wort. Pour the required water amount over the draff bit by bit. Always let a bit of water drip through until the draff does not float in the water anymore and then pour in more water.

After the lautering process you can measure the wort again to keep track of your extract value. Stir first to get a homogeneous liquid.

Boiling

![]()

Boiling of wort causes several chemical reactions, such as sterilization and concentration, unfolding of hop flavours, aroma and bitterness through isomerization, inactivation of enzymatic processes and precipitation of proteins.

During lautering, the wort will have cooled down a little. Now you have to heat it up again to 100 °C (212 °F). Put the lid on your kettle for this and make sure that the lid has an opening to let the steam out.

While the brew kettle heats up take the hops out of the package and weigh them according to your recipe. Usually, there will be two hoppings during boiling, so you will get two different portions.

Add the first portion of hops when boiling temperature is reached. Let the wort boil for the time given in your recipe. After that add the second hop portion and let the wort boil again for the stated time.

You should do another pH Test in between the two hoppings at around 30 minutes after the first hopping. The value should be approximately pH 5.2.

Separating the Hot Trub

In industrial brewing, there are special “whirlpools” where trub is separated by centrifugal force. You can do it manually if you stir the wort strongly in one direction until you see a vortex. The trub will be sucked to the center of the brew kettle. Close the brew kettle immediatly after stirring and let it rest for about 10 minutes.

If you put the cooling coil above the center, it will “catch” the trub in the center so it stays in the brew kettle when you pour out the wort. This will be explained in the following steps.

Cooling

![]()

As yeast is not a plant but a living creature, it does not survive in very hot surroundings. Therefore, the wort needs to be cooled down before yeast is added. A temperature of about 15 °C to 20 °C (59 °F to 68 °F) is best for top-fermented beers.

Use a cooling coil to speed up the cooling process of your brew. It has hoses on both ends, so you will need a water outlet to pump cold water through the coil and a vessel for drain water.

Cover the brew kettle during this procedure to prevent insects from falling into the wort – this could contaminate your beer with e.g. lactic acid bacteria that would destroy the beer’s taste.

Measuring of Specific Gravity

![]()

To make sure that the quality and the gravity levels remain consistent from one batch to the other, the specific gravity (SG) will be measured during this process. SG is the ratio between the density of the liquid, compared to the density of a reference, like water. When you measure the SG of the beer before fermentation has started, it is called “Original Gravity”.

Now is the right time to measure and determine your wort's Original Gravity (SG/°Plato). Based on this value, further parameters (e.g. alcohol during and after fermentation) can be calculated.

Take the sample directly out of the brew kettle for this so you only measure your wort, no yeast. Filter your sample before measuring it (e.g. with a standard coffee filter).

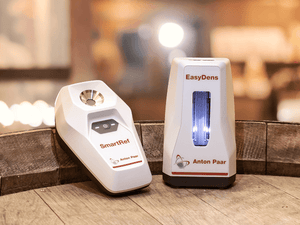

If you use a hydrometer or refractometer for your measurement, you will need to make adjustments based on temperature, when you are calculating the Originial Gravity of your brew. If you are seeking highly accurate readings with no risk of contaminating your brew, take a look at the measurement principle of the EasyDens Smart Hydrometer.

Fermentation

![]()

Fermentation is the process that transforms wort into beer.

Prepare the yeast and barrel(s) while your wort is cooling down, so you have them at hand when the wort is ready.

Mix the yeast with water according to your recipe.

- Let the mixture rest to activate the yeast. Detailed instructions might depend on the kind of yeast you are using and are often given on the package.

- Pour the yeast into the barrel(s) you prepared.

- Put a funnel with a fine-mesh sieve on your barrel(s). Open the outlet of the brew kettle and let the wort slowly run into the barrel.

When the barrel(s) are filled, whisk the liquid to blend the yeast with the wort and to aerate the wort before fermentation starts. Then firmly close the barrel(s) with an airlock.

Now the fermentation starts: Let the beer ferment in a dark place, according to your recipe. The ambient temperature should be approximately 20 °C (68 °F) for top fermentation and 12 °C (54 °F) for bottom fermentation.

Bottling/Secondary Fermentation

![]()

Final Gravity is the specific gravity that is measured after fermentation is completed and before adding priming sugar. It shows the amount of unfermentable sugars remaining in the beer and is used to calculate the estimated alcohol content of your brew.

Check the decreasing apparent extract on a daily basis by taking a few mL of the sample out of the spigot of the barrel. If the apparent extract does not change anymore (approx. after seven to 14 days), you can calculate the amount of sugar for priming. If you don’t want to do this manually, you can use this calculator to help you. The sugar has to be dissolved and carefully mixed with the fermented beer before you fill it into glass bottles.

The secondary fermentation will take place in the closed glass bottles and generates the desired CO₂ content for your beer. Finally, let the beer mature for two to three weeks at preferably low temperatures around 4 °C (39 °F).

Enjoy your Homebrew

Finally - refrigerate and enjoy your own beer!